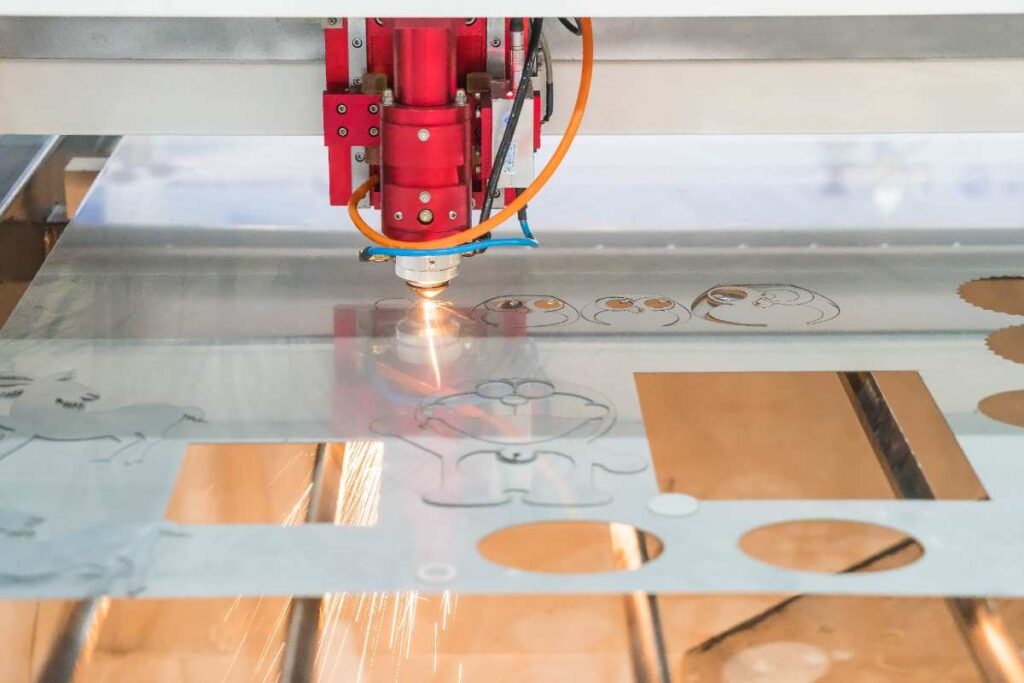

The future of precision manufacturing is integral to the advancement and sustainability of various industries that rely on exact measurements and meticulous attention to detail. As the need for precision and efficiency increases, the manufacturing sector continues to innovate and adopt new technologies to meet these demands. One such innovation that stands at the forefront of precision manufacturing is the application of tube laser cutting services. This technology heralds a promising future for manufacturers, offering unparalleled accuracy, speed, and flexibility.

Breaking New Ground in Efficiency and Precision

Tube laser cutting services have revolutionised the way that manufacturers approach projects that require intricate detailing and precise measurements. This technology allows for the cutting of materials with extraordinary accuracy, creating complex shapes and designs that would have been difficult or impossible to achieve with traditional cutting methods.

The efficiency of laser cutting is noteworthy, as it dramatically reduces the amount of time required to produce components. As the technology continues to progress, the speed at which laser cutters operate is expected to increase further, thereby enhancing productivity within the manufacturing sector.

Innovation in Material Compatibility

One of the significant advancements in tube laser cutting services is the broadening range of materials that can be effectively and cleanly cut with lasers. Modern laser cutters can now handle a variety of materials, including different grades of steel, aluminium, and even some types of plastic. This expansion in material compatibility opens up new applications across industries such as automotive, aerospace, construction, and medical devices, where material specifications are stringent.

Enhancements in Precision and Quality Control

The precision offered by tube laser cutting technology ensures that components are created with exceptional accuracy, contributing to the overall quality of the final product. This is particularly critical in sectors where a high degree of precision is essential for the performance and safety of the components, such as in the aerospace industry.

Moreover, the ability to maintain such precision consistently over large production runs highlights the reliability of laser cutting in quality control. This consistency not only improves the product quality but also minimises waste, making the process more cost-effective and environmentally friendly.

Customisation and Flexibility in Design

Flexibility in design is another area where tube laser cutting services excel. Unlike conventional cutting methods that can be restrictive and may require special tooling for custom designs, laser cutting provides the freedom to create complex shapes and patterns without additional costs or time delays.

The ability to quickly and easily adapt to new designs is essential for custom manufacturing and prototyping. It allows manufacturers to iterate more rapidly during the development phase and to respond swiftly to market demands or changes in design specifications.

Integration of Automation and Software Innovations

As we look towards the future, the integration of automation into laser cutting services is anticipated to play a significant role. Automated loading and unloading systems, as well as advancements in software that facilitate more efficient nesting and pattern making, are indicators of where the industry is heading.

Automation not only increases productivity but also minimises human error, further enhancing the consistency of the output. Pairing this automation with sophisticated software enables the manipulation of designs in real-time and optimises material usage, reducing waste and cost.

Addressing the Skills Gap through Technology

An ongoing challenge within the manufacturing field is the skills gap, where the demand for skilled workers surpasses supply. Through technologies such as tube laser cutting, the skills required for operation can be less manual and more technical, which paves the way for a new generation of tech-savvy workers.

Training programmes and educational initiatives focused on these new technologies are essential to equip the workforce with the necessary knowledge and skills. By doing so, the industry can mitigate the skills gap and usher in a new era of manufacturing that melds traditional craftsmanship with modern technology.

Conclusion

The advancement of tube laser cutting services is a testament to the steady progression towards greater precision, efficiency, and flexibility in the manufacturing sector. By harnessing the capabilities of this technology, manufacturers can anticipate a future that not only meets the current demands but one that pushes the boundaries of what is possible in precision manufacturing.

As industries continue to evolve and place a higher emphasis on precision, the role of innovative technologies like tube laser cutting will become increasingly vital. This is not only in terms of production but also in ensuring the resilience and adaptability of the manufacturing sector in an ever-changing global market.

Looking ahead, the continued development and adoption of tube laser cutting services promise to enrich the field of precision manufacturing. The future will likely see more integrated, intelligent, and environmentally sustainable production processes that reinforce the significance of laser technology in crafting the world of tomorrow.